ACAT HB™ Made in the USA

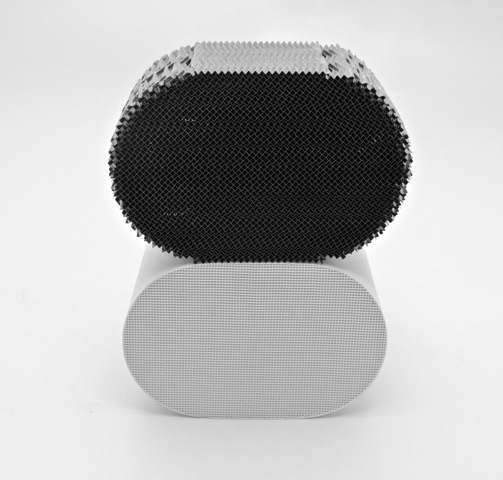

ACAT’s proprietary metallic HB™ substrate technology is unique in the market. HB™ stands for HerringBone pattern, which is at the core of every ACAT HB™ metallic substrate catalytic converter.

Ceramic substrate cells function like a bundle of individual straws, trapping exhaust gases in a single channel where they remain until they exit. Ceramic product is commoditized. The same solution is used by all the competition. The only variation with ceramic substrates is how many cells there are. 400 CPSI (CPSI means cells per square inch) is typical for EPA aftermarket, 600 CPSI is typical for CARB aftermarket, and 200 CPSI is considered high flow.

Can you tell the difference with ACAT HB™ substrate technology?

ACAT HB™ substrates use an entirely different construction allowing exhaust gases to intermix and flow through the substrate. Our HB™ pattern creates a turbulent exhaust flow continuously breaking the boundary layer effect used by all ceramic substrates.

Developed at Delphi/GM enduring 5,100,000 miles of general fleet durability testing with no failures, ACAT HB substrates meet OEM durability requirements having been used and tested on some of the worlds most advanced engine platforms from 5.3L to 6.2L V8 engines

Designed specifically for exhaust gas velocities encountered in today’s engine architectures, our ACAT HB™ solution is meant as a plug and play advantage. Our audited ISO 9001 and OEM substrate wash coat provider has specified the most current OEM wash coat technology for our converters. Benchmarking alternative converter units on the market with high return rates has driven us to specify a higher PGM loaded wash cost as standard ensuring you are getting a superior product.